CelLink

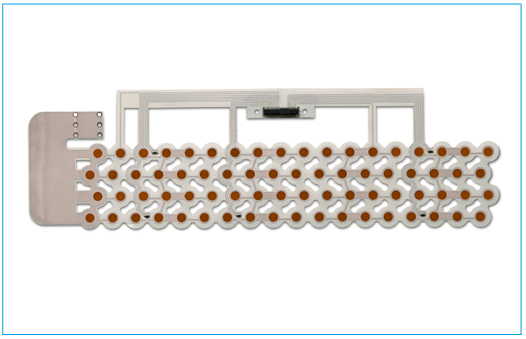

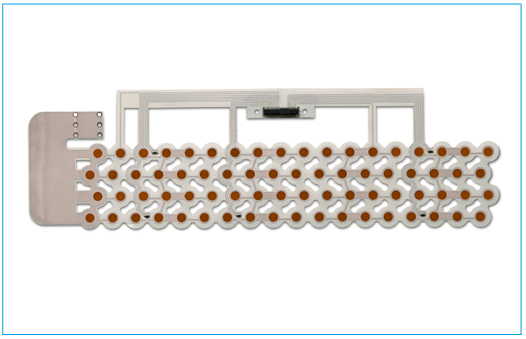

High-conductance, large-area flexible circuits

for the clean power revolution

Device stacks engineered for superior thermal, mechanical, and electrical performance

-----

Unique dielectric materials for high speed data transmission, low stiffness, fire retardancy, and more

-----

Patterned adhesive backings and back-bared metal structures ensure ease of assembly for end users

Up to 2m x 1m part footprint

-----

Coming soon: 3.5m x 1m

Copper thickness 17.5 - 250 µm

Aluminum thickness 17.5 - 500 µm

Multi-layer conductor assemblies available

-----

Aluminum conductors available with proprietary coatings that provide a highly reliable solderable surface

-----

Other metals, alloys, and tempers available upon request

CelLink’s high-conductance circuits integrate busing, fusing, voltage monitoring, and temperature monitoring wiring systems into a single circuit.

CelLink’s circuits provide much greater control over power and data transmission than traditional round wire – at 1/4th the weight and 1/10th the volume.

Thanks to a completely tool-less manufacturing process, CelLink’s minimum order quantity is one.

View Details

CelLink’s high-conductance circuits integrate busing, fusing, voltage monitoring, and temperature monitoring wiring systems into a single circuit.

CelLink’s circuits provide much greater control over power and data transmission than traditional round wire – at 1/4th the weight and 1/10th the volume.

Thanks to a completely tool-less manufacturing process, CelLink’s minimum order quantity is one.

View Details